During Vapor Removal From A Low Pressure System

During vapor removal from a low pressure system. A rupture disc on a recovery vessel for low-pressure refrigerants relieves at. Wc h2 h1 2-3. What should be on and what should be off during vapor removal from a low-pressure refrigeration system.

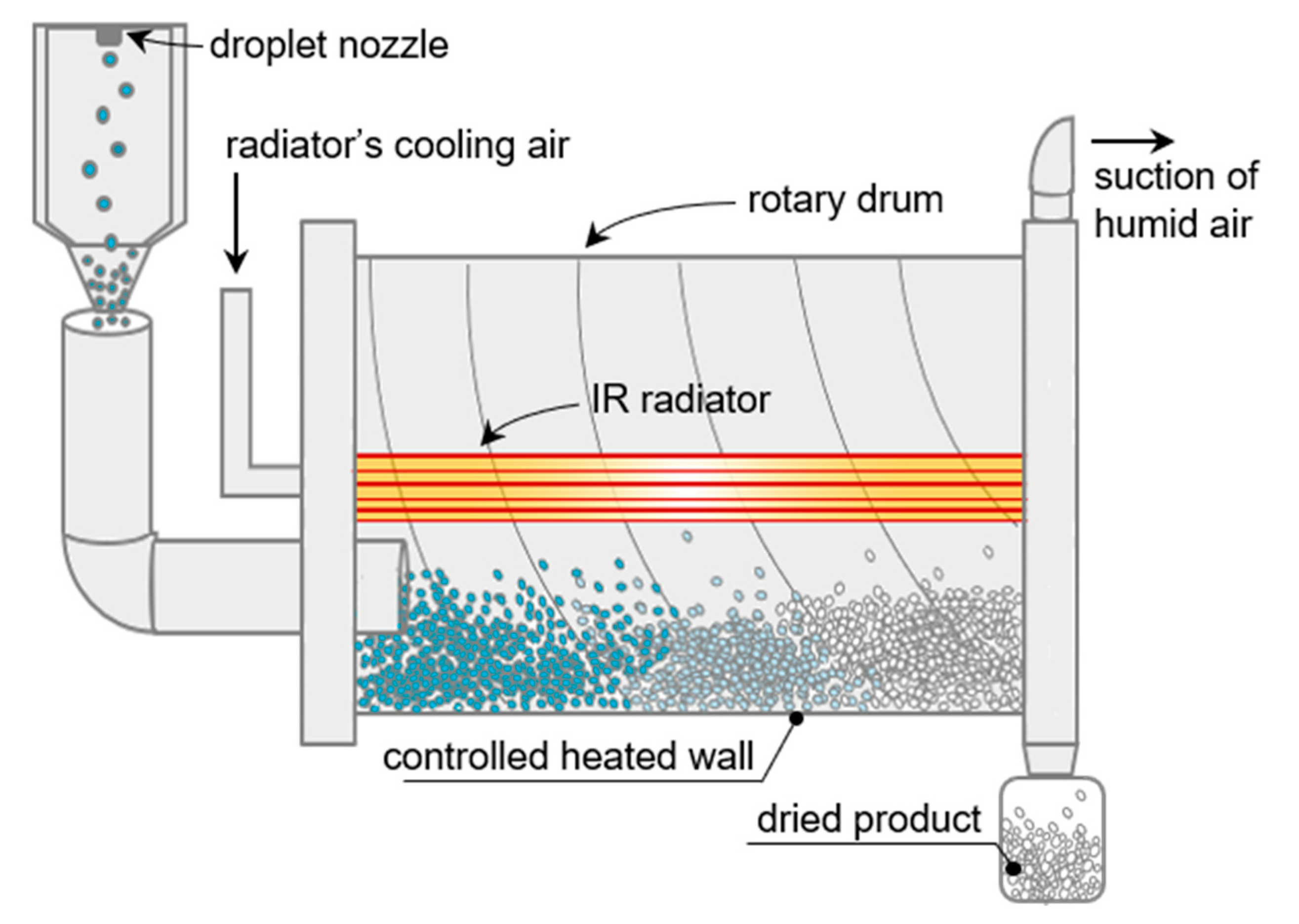

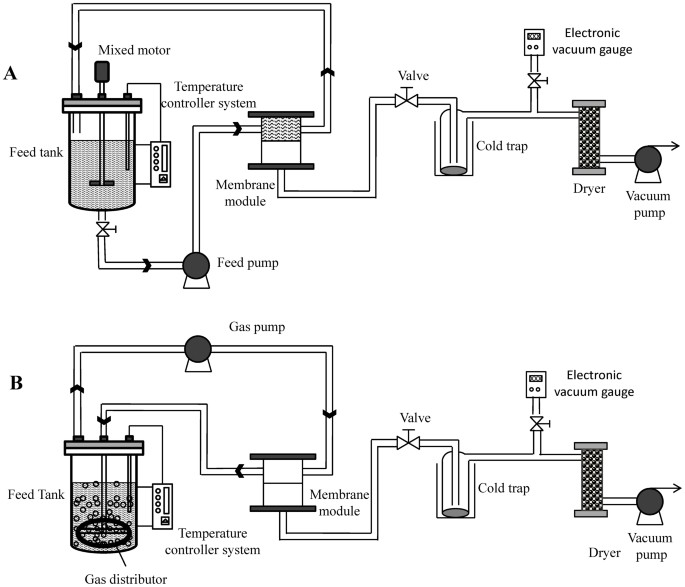

Installing Vapor Recovery Units on Storage Tanks Contd Economic and Environmental Benefits. That provides the low-pressure suction for the VRU system. From the system during the standing pressure tests where the quality of the vacuum will be measured.

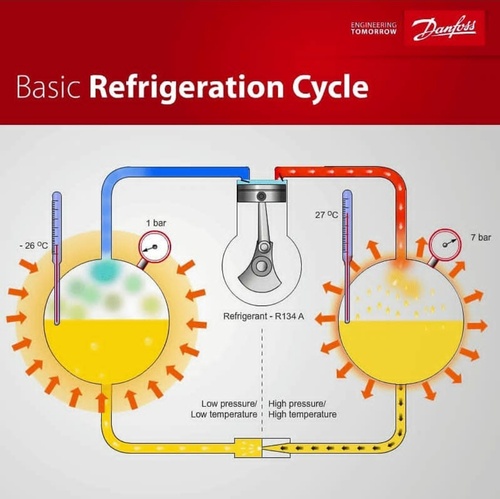

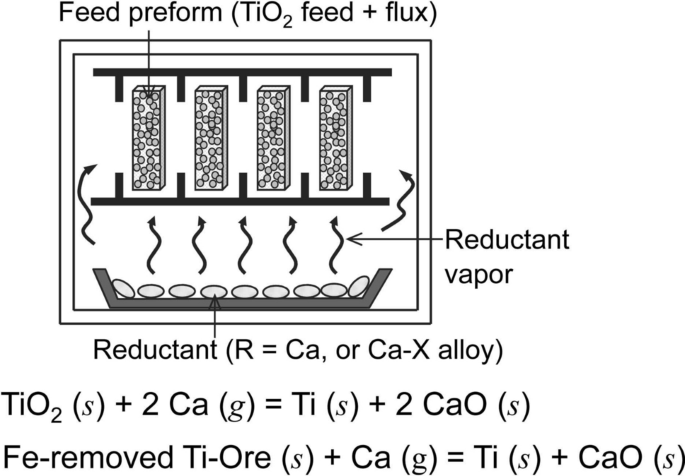

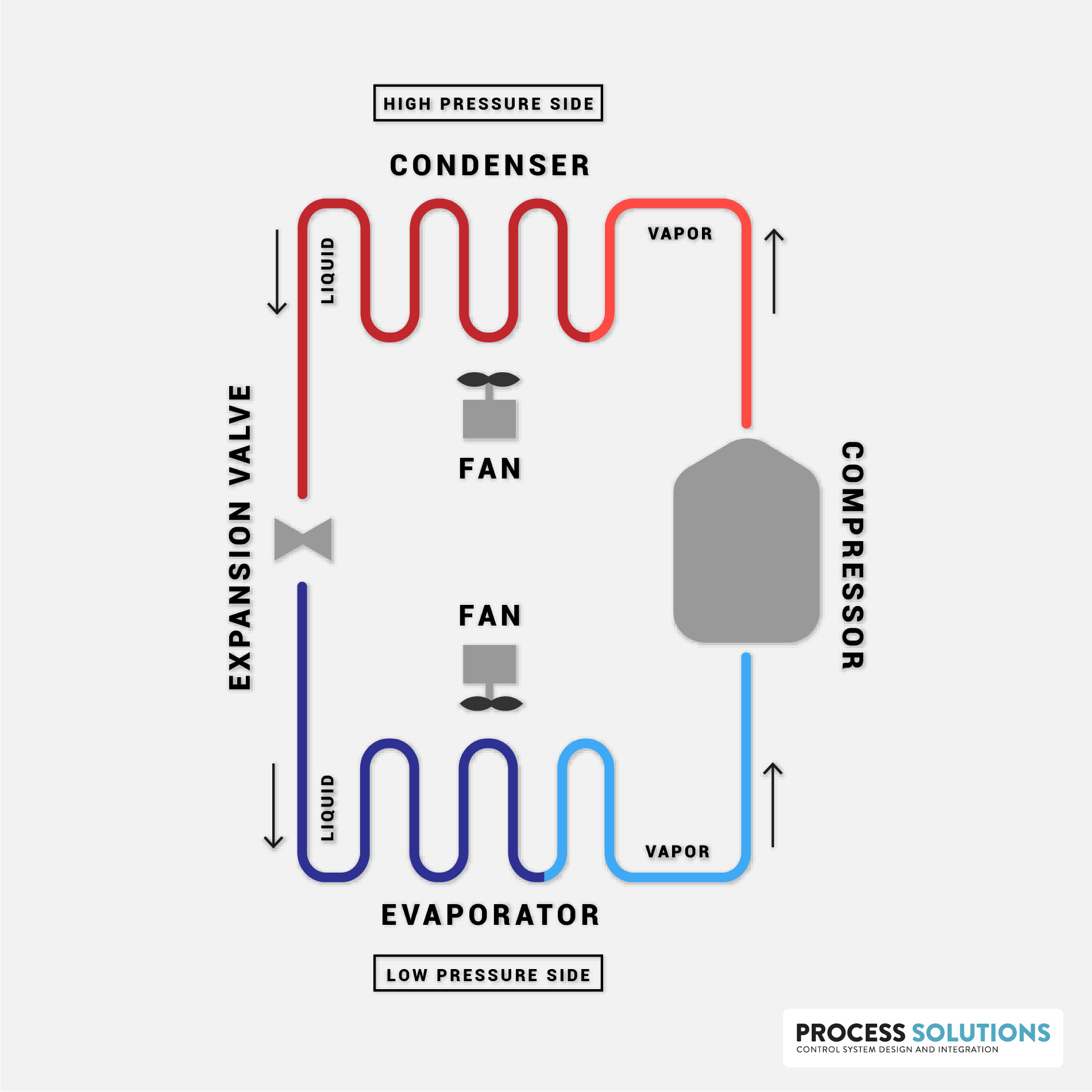

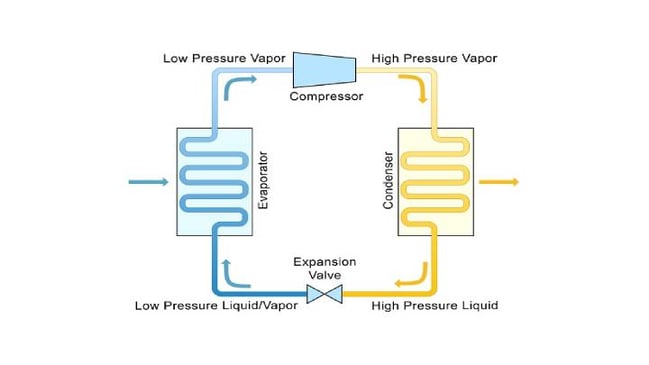

Charging refrigerant liquid into a refrigeration system under a 29 inch Hg vacuum can cause the. Water pumps recovery compressor recovery condenser. Figure 1 depicts a generic catalytic oxygen removal system.

Many times several. On reaching the desired level of vacuum resin which is atmospheric pressure is allowed to impregnate the coils at a low pressure. What should be on and what should be off during vapor removal from a low-pressure refrigeration system.

Removal of the air System Evacuation. As a result of the pressure difference resin impregnates the innermost parts of the. A heater used on a recovery vessel aids in the faster transfer of ___ from the chiller during recovery.

QH h2 h3. Wait for at least a few minutes to see if the system pressure rises before charging. System water to freeze.

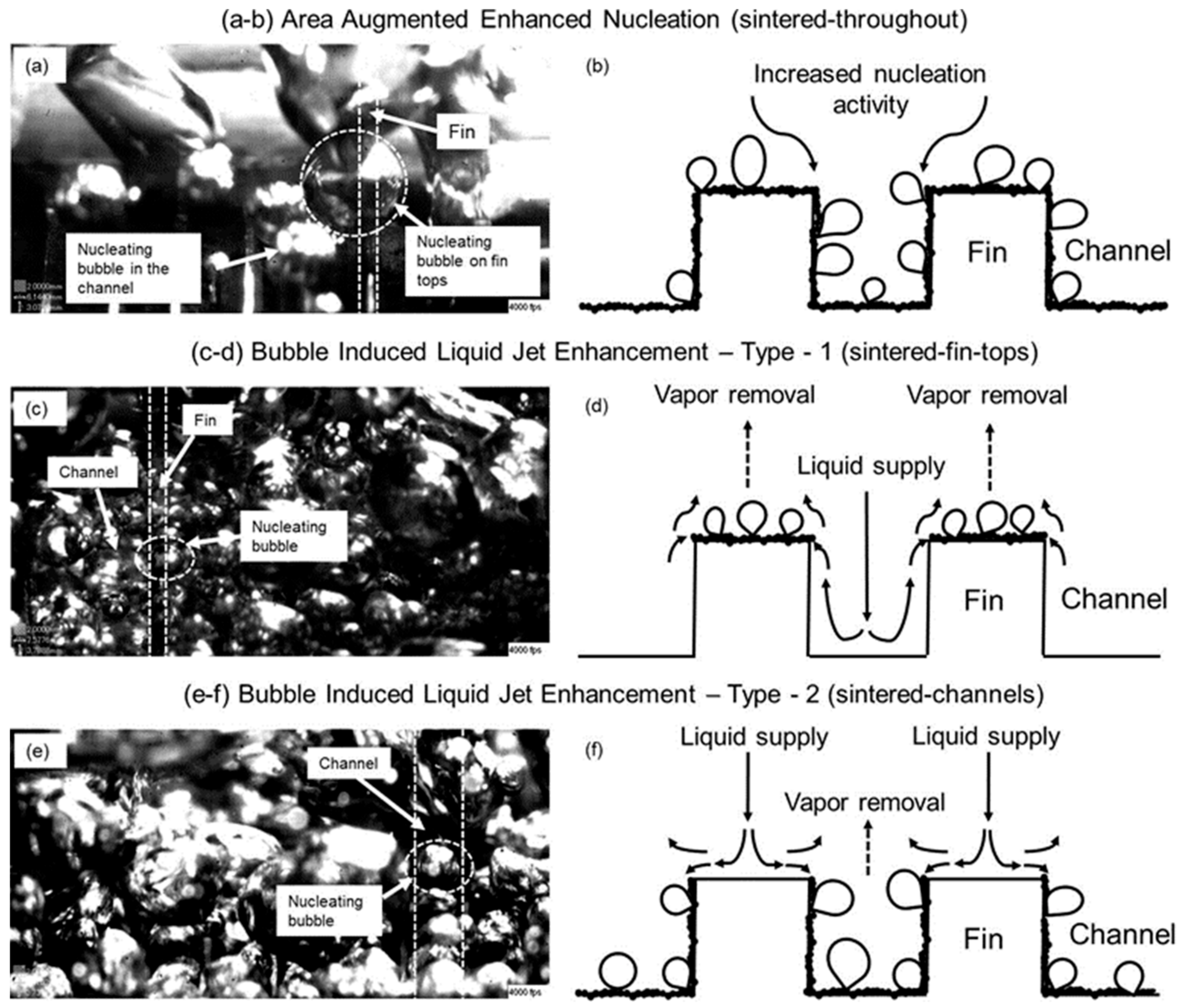

55 rows When using the _____ method to recover refrigerant from a low pressure chiller the recovery. When does ASHRAE Standard 15-2013 require that each machinery room activate an.

Immediately disconnect the recycling or recovery equipment and open the systern for service.

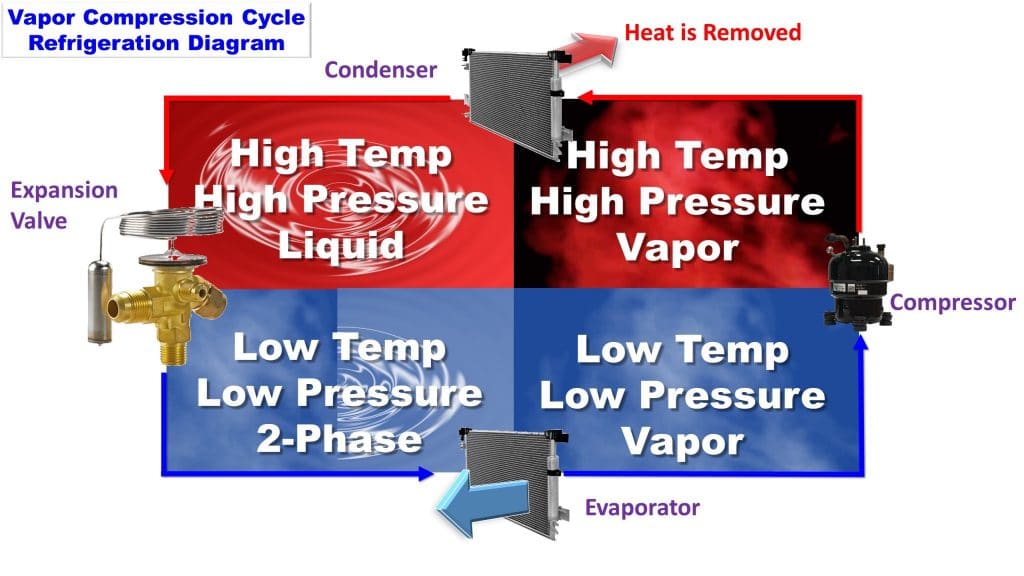

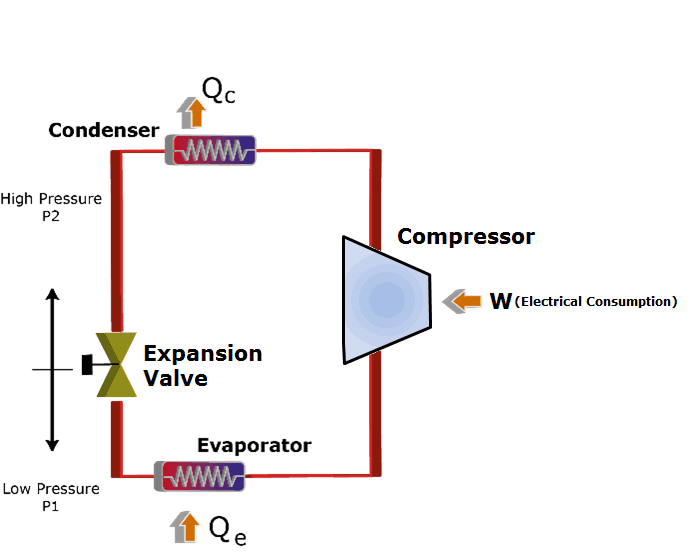

According to the present invention low pressure chemical vapor deposition apparatus for removing a particulate matter is provided which includes a bell jar a quartz tube housed in the bell jar and a slotted quartz boat housed in the quartz tube for holding a wafer. The system water pumps should be on and the recovery compressor should be off. During storage light hydrocarbons dissolved in. During this process the working substance rejects most of its energy to the condenser cooling water. A heater used on a recovery vessel aids in the faster transfer of ___ from the chiller during recovery. The typical setting for the high-pressure cut out control on recovery unit used for evacuating the refrigerant from a low-pressure chiller is 10 psig Refrigerant removal. QH h2 h3. According to the present invention low pressure chemical vapor deposition apparatus for removing a particulate matter is provided which includes a bell jar a quartz tube housed in the bell jar and a slotted quartz boat housed in the quartz tube for holding a wafer. P 1 760 Torr V 1 120 Liters Now if we open the valve between vessels 1 and 2 and allow sufficient time for the system to equilibrate we read pressures at TC1 and TC2 to be 500 Torr.

A rupture disc on a recovery vessel for low-pressure refrigerants relieves at. Figure 1 Catalytic Oxidation Unit. The system water pumps should be on and the recovery compressor should be off. On reaching the desired level of vacuum resin which is atmospheric pressure is allowed to impregnate the coils at a low pressure. What should you do after reaching the required recovery vacuum on a low-pressure appliance. During vapor removal from a low pressure refrigeration system. That provides the low-pressure suction for the VRU system.

Post a Comment for "During Vapor Removal From A Low Pressure System"